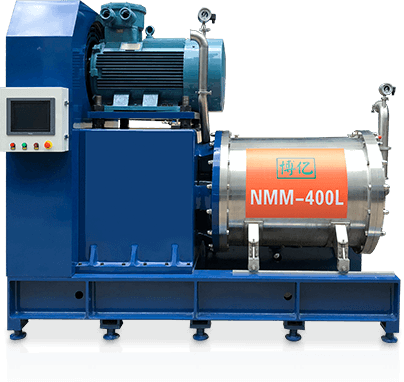

This production line boasts high levels of automation, digitalization, and intelligence, dedicated to delivering efficient

and premium-quality production of silicon-carbon anode materials. Employing advanced processing technologies and equipment,

coupled with tailor-made research and manufacturing solutions, ensures consistency and stability in the silicon-carbon anode materials produced.

1,Equipped with mass-production capabilities on a ten-thousand-ton scale, capable of fulfilling the requirements of large-scale manufacturing.

2,Tailored research and development, as well as manufacturing solutions, are provided based on the client's specific requirements and product specifications.

Contact us now

Contact us now

Contact us now

Contact us now