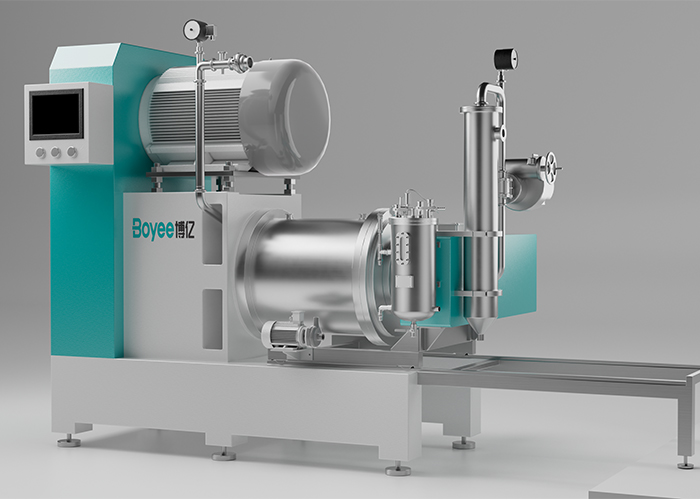

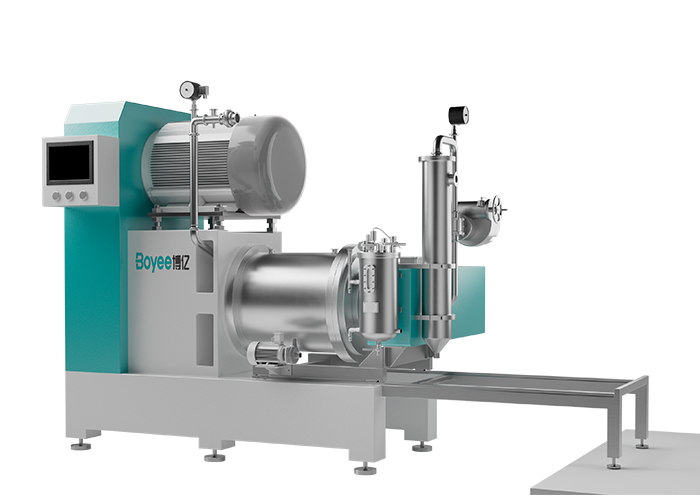

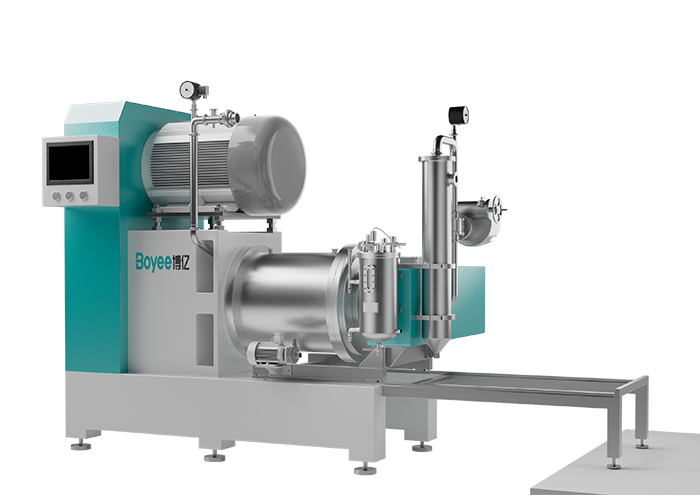

| LMM-400L |

400 |

315 |

0-927 |

0.05-1 |

8600 |

4600×1600×2400 |

View

* The picture is a display machine, subject to the actual equipment

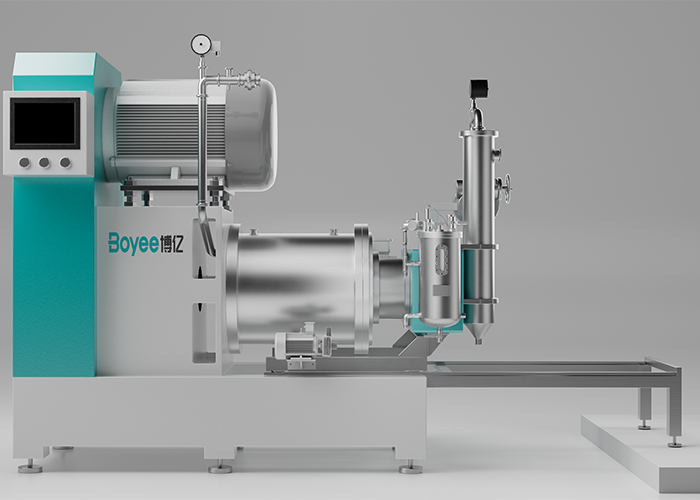

LMM-400L

- Volume of grinding chamber(L): 400

- Grinder driving power(kw): 315

- Decentralizer speed(r/min): 0-927

- Diameter of grinding medium(mm): 0.05-1

- Machine weight(kg): 8600

- Overall dimension(mm): 4600×1600×2400

Equipment characteristics:

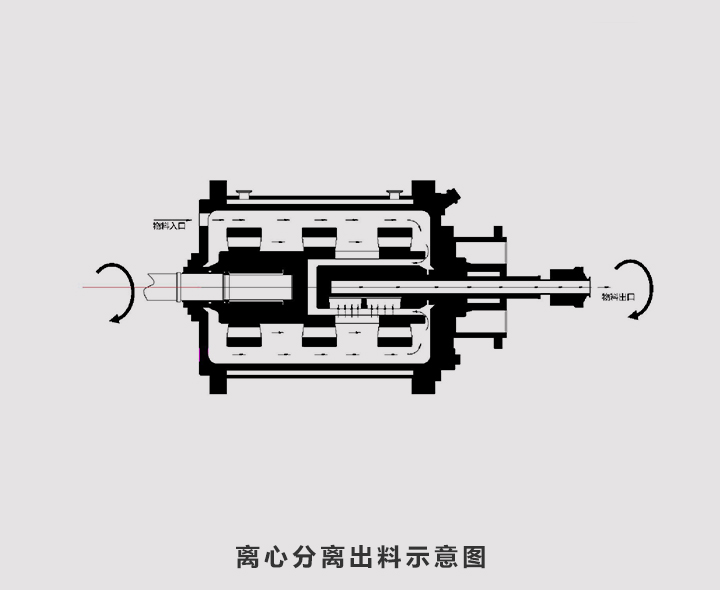

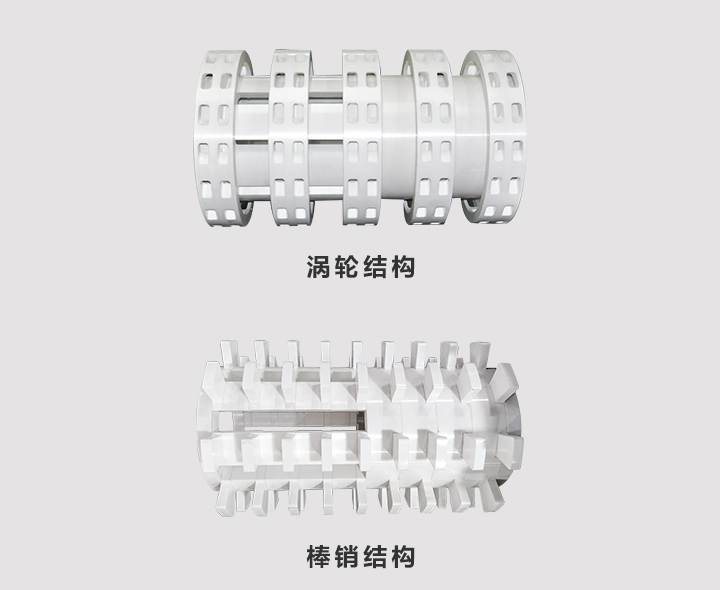

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

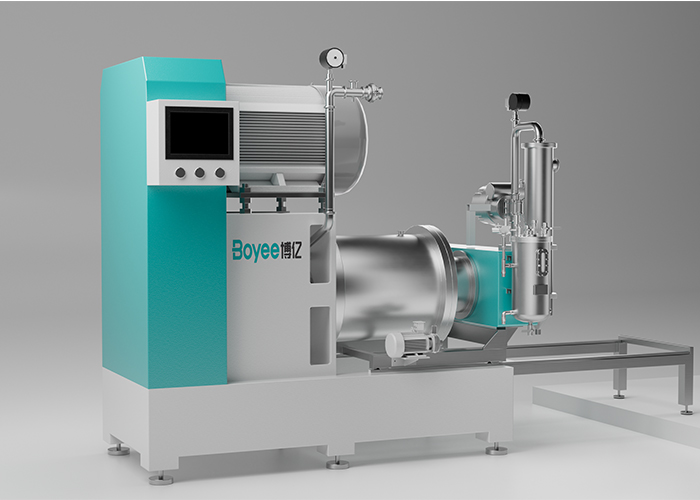

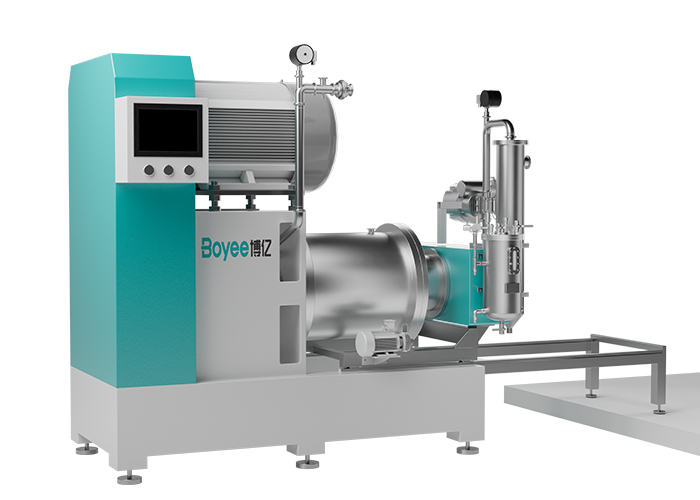

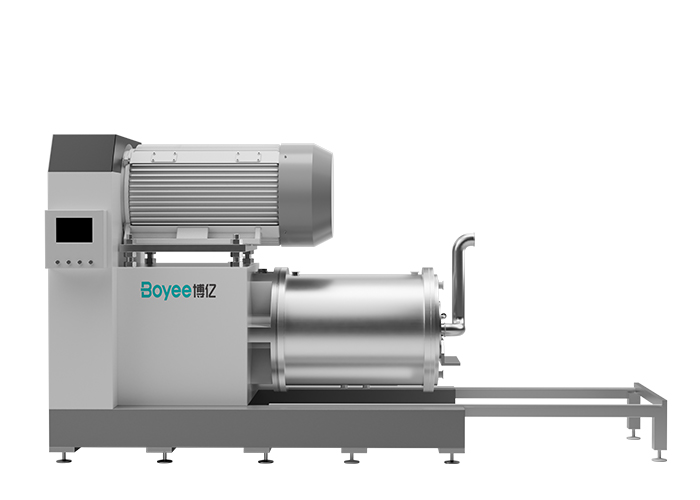

| LMM-150L |

120-180 |

160 |

0-627 |

0.05-1 |

5600 |

4500×1700×2400 |

View

* The picture is a display machine, subject to the actual equipment

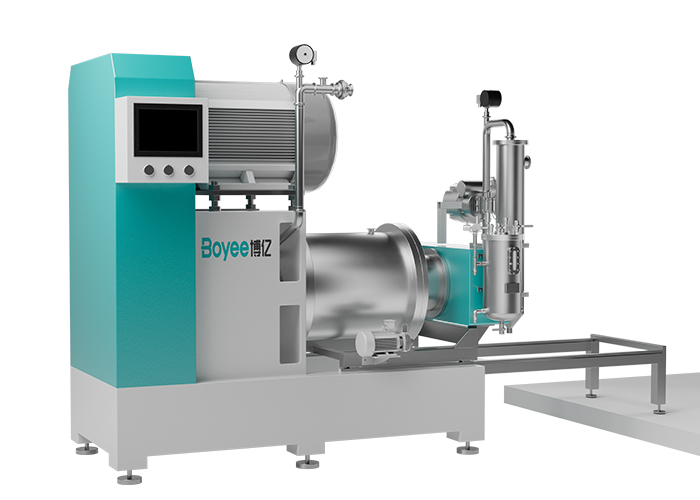

LMM-150L

- Volume of grinding chamber(L): 120-180

- Grinder driving power(kw): 160

- Decentralizer speed(r/min): 0-627

- Diameter of grinding medium(mm): 0.05-1

- Machine weight(kg): 5600

- Overall dimension(mm): 4500×1700×2400

Equipment characteristics:

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

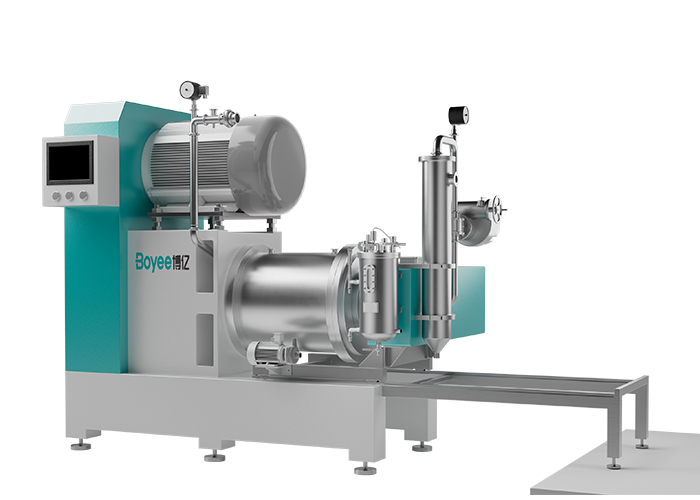

| LMM-60L |

58 |

75 |

0-776 |

0.05-1 |

2800 |

3290×1478×1950 |

View

* The picture is a display machine, subject to the actual equipment

LMM-60L

- Volume of grinding chamber(L): 58

- Grinder driving power(kw): 75

- Decentralizer speed(r/min): 0-776

- Diameter of grinding medium(mm): 0.05-1

- Machine weight(kg): 2800

- Overall dimension(mm): 3290×1478×1950

Equipment characteristics:

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

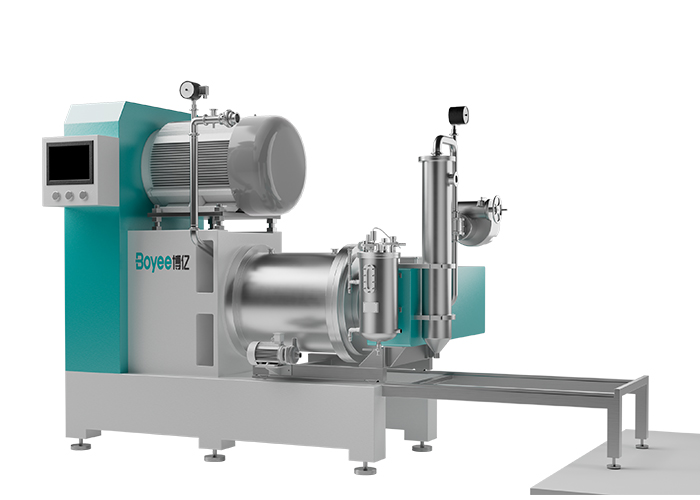

| LMM-30L |

30 |

45 |

0-1000 |

0.05-1 |

2100 |

1800×1300×1800 |

View

* The picture is a display machine, subject to the actual equipment

LMM-30L

- Volume of grinding chamber(L): 30

- Grinder driving power(kw): 45

- Decentralizer speed(r/min): 0-1000

- Diameter of grinding medium(mm): 0.05-1

- Machine weight(kg): 2100

- Overall dimension(mm): 1800×1300×1800

Equipment characteristics:

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

| LMM-10L |

10 |

18.5 |

0-1460 |

0.05-1 |

1500 |

1800×1200×1550 |

View

* The picture is a display machine, subject to the actual equipment

LMM-10L

- Volume of grinding chamber(L): 10

- Grinder driving power(kw): 18.5

- Decentralizer speed(r/min): 0-1460

- Diameter of grinding medium(mm): 0.05-1

- Machine weight(kg): 1500

- Overall dimension(mm): 1800×1200×1550

Equipment characteristics:

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

| LMM-3L |

3 |

7.5 |

0-1450 |

0.1-1 |

800 |

1400×1100×1680 |

View

* The picture is a display machine, subject to the actual equipment

LMM-3L

- Volume of grinding chamber(L): 3

- Grinder driving power(kw): 7.5

- Decentralizer speed(r/min): 0-1450

- Diameter of grinding medium(mm): 0.1-1

- Machine weight(kg): 800

- Overall dimension(mm): 1400×1100×1680

Equipment characteristics:

l 创新离心式出料 l 物料研磨与分离独立运行 l 适用于低粘度产品 l 研磨介质最小可达0.05mm l 可选涡轮式及棒销式研磨系统 l 更精细的研磨与分散效果 l 卓越的冷却性能 l 多种材质满足个性化需求 l 易于操作与清洁

|

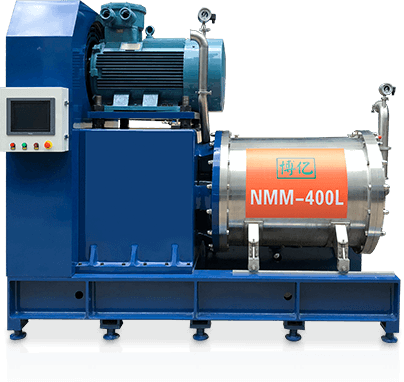

| NMM-90L |

98 |

75-90 |

0-776 |

≥0.2 |

3050 |

3290×1478×1950 |

View

* The picture is a display machine, subject to the actual equipment

NMM-90L

- Volume of grinding chamber(L): 98

- Grinder driving power(kw): 75-90

- Decentralizer speed(r/min): 0-776

- Diameter of grinding medium(mm): ≥0.2

- Machine weight(kg): 3050

- Overall dimension(mm): 3290×1478×1950

Equipment characteristics:

l 更高的流量 l 卓越的高粘度物料处理能力 l 可选TurboMax自主研发涡轮及棒销式研磨系统 l 可选陶瓷、高分子及合金材质元件 l 更长的滤网使用寿命 l 全型号满足从实验室到规模生产需求 l 日常维护保养简单而快捷 l 低噪声影响

|

Contact us now

Contact us now

Contact us now

Contact us now