1,Throug advanced data analysis and management systems, real-time monitoring of production data is achieved, enabling efficient production scheduling and optimization.

2,The solution can be tailored to customer needs, is easily expandable, and adapts to the varying production demands of enterprises at differents tages of their development.

3,A Data Management System is implemented to achieve full-process tracing of product quality and production data, enhancing product quality while reducing the rate of defects.

4,Boyee's intelligentproduction line optimizes production processes and resource allocation, minimizing unnecessary waste andloss, thereby reducing operational costs.

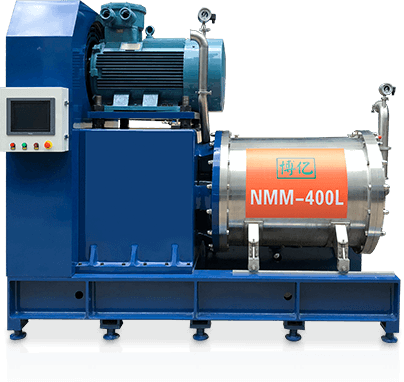

Process flow:Unpacking and feeding system=>Emulsification dispersion system=>Homogenizing system=>Dispersion grinding system=>Measuring and dosing=>Pneumatic conveying=>Spray drying system=>Airflow milling system.=>Finished product packaging system

Contact us now

Contact us now

Contact us now

Contact us now