Superior performance comes from the reliable inner --

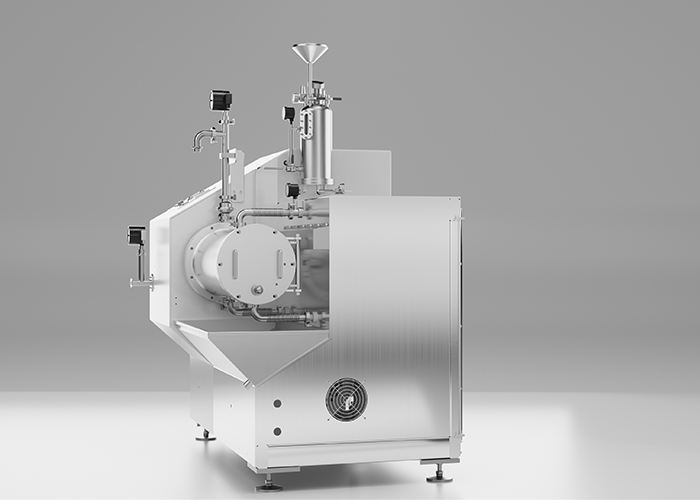

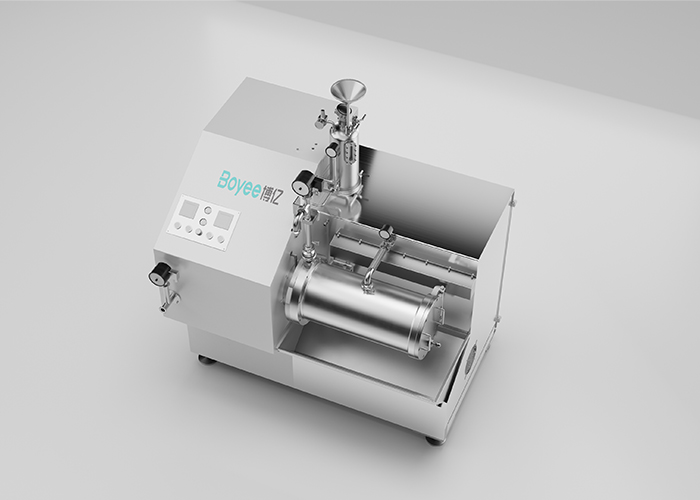

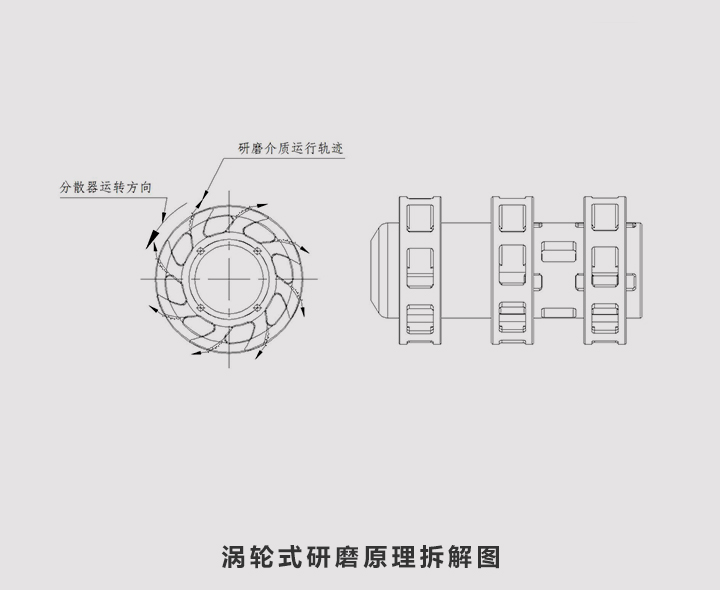

TurboMax independently developed turbine grinding system

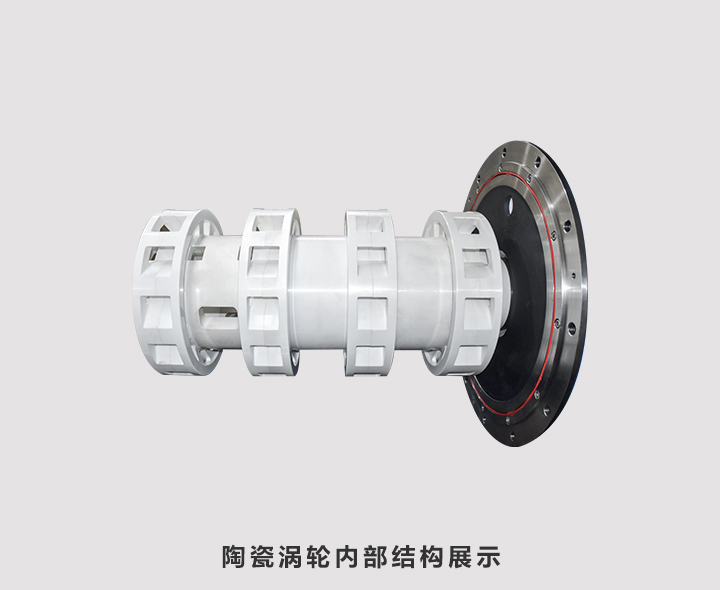

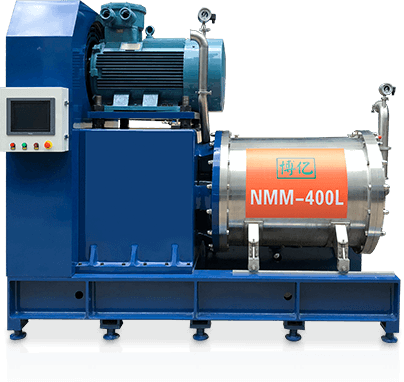

Our BYZr sand mill uses an exclusive TurboMax turbine grinding structure, which effectively prevents excessive dispersion of materials and provides a gentler and more detailed grinding effect. In addition, it can be equipped with PurCeram ceramic process independently developed by Boyee. From the rotor to the grinding chamber, the ceramic structure is completely adopted, which can eliminate the pollution of metal ions on the materials, and has excellent wear-resisting performance, effectively ensuring the purity of materials and extending the service life and maintenance cycle of the equipment.

Contact us now

Contact us now

Contact us now

Contact us now