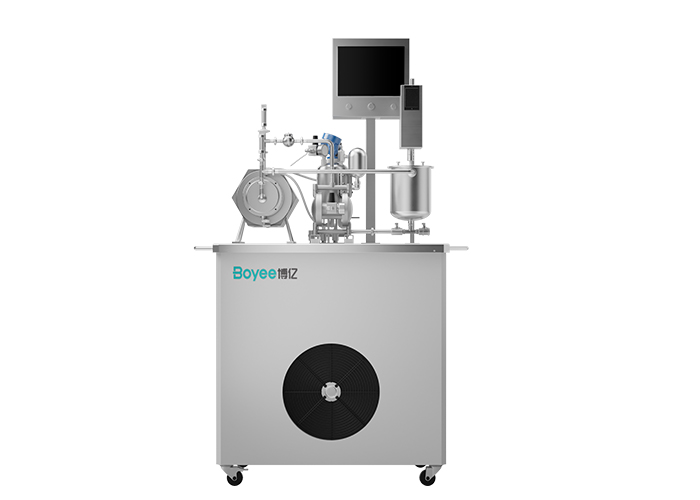

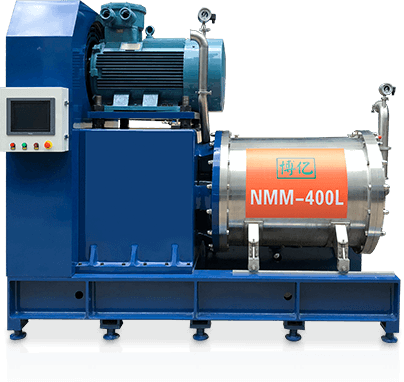

NMM-90L filter screen nano sand mill

- Grinding chamber volume (L): 98

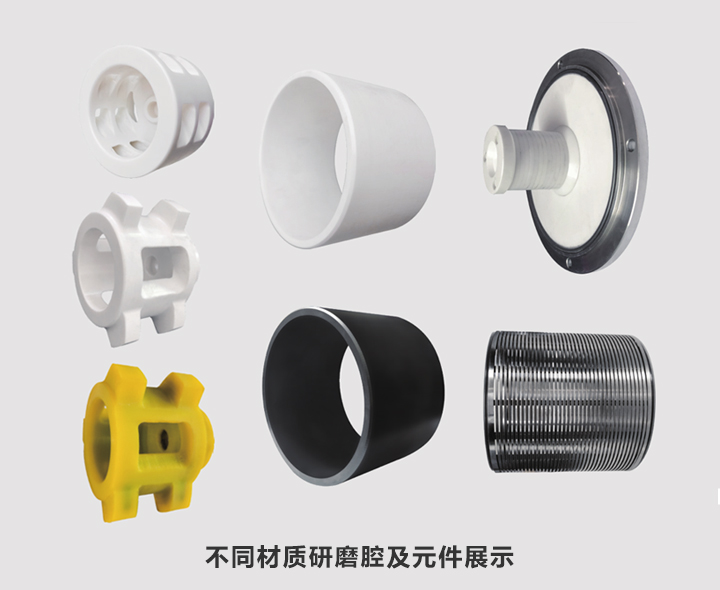

- Motor power (kw): 75-90

- Disperser speed(r/min): 0-776

- Medium filling volume(%): 60-80

- Equipment weight(kg): 3050

- Overall dimension L*W*H(mm): 3290x1478x1950

Equipment characteristics:

1. Turbine structure design;

2. The grinding chamber of super wear-resistant ceramic structure is designed without metal pollution;

3. Special mechanical seal, unique design, stable operation;

4. Small floor space, stable equipment and low noise during operation;

5. Special cooling circuit and application of high thermal conductivity materials can control lower grinding temperature;

6. Large flow circulation design.

7. Turbine structure design;

8. The grinding chamber of super wear-resistant ceramic structure is designed without metal pollution;

9. Special mechanical seal, unique design, stable operation;

10. Small floor space, stable equipment and low noise during operation;

11. Special cooling circuit and application of high thermal conductivity materials can control lower grinding temperature;

Contact us now

Contact us now

Contact us now

Contact us now