- Home

-

Product/solution

Grinding scattered

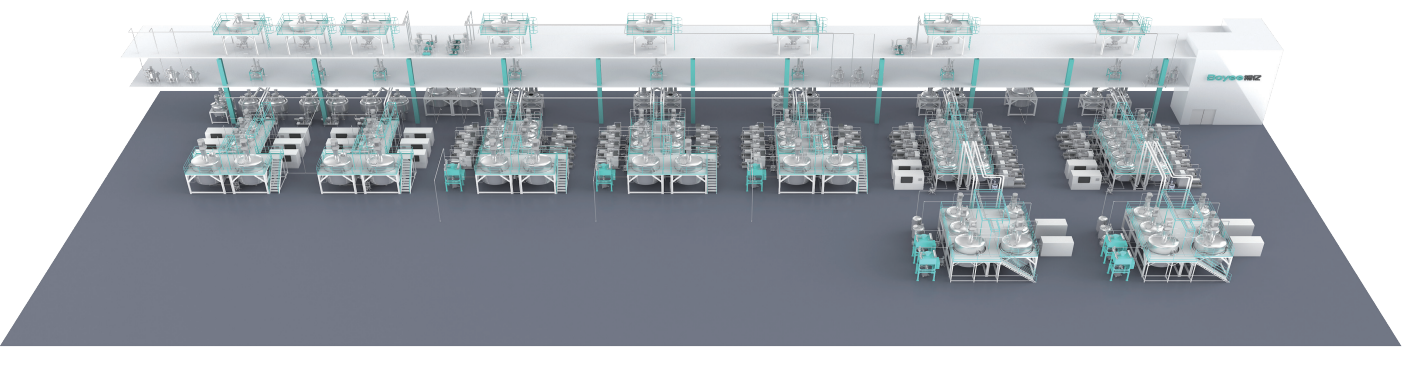

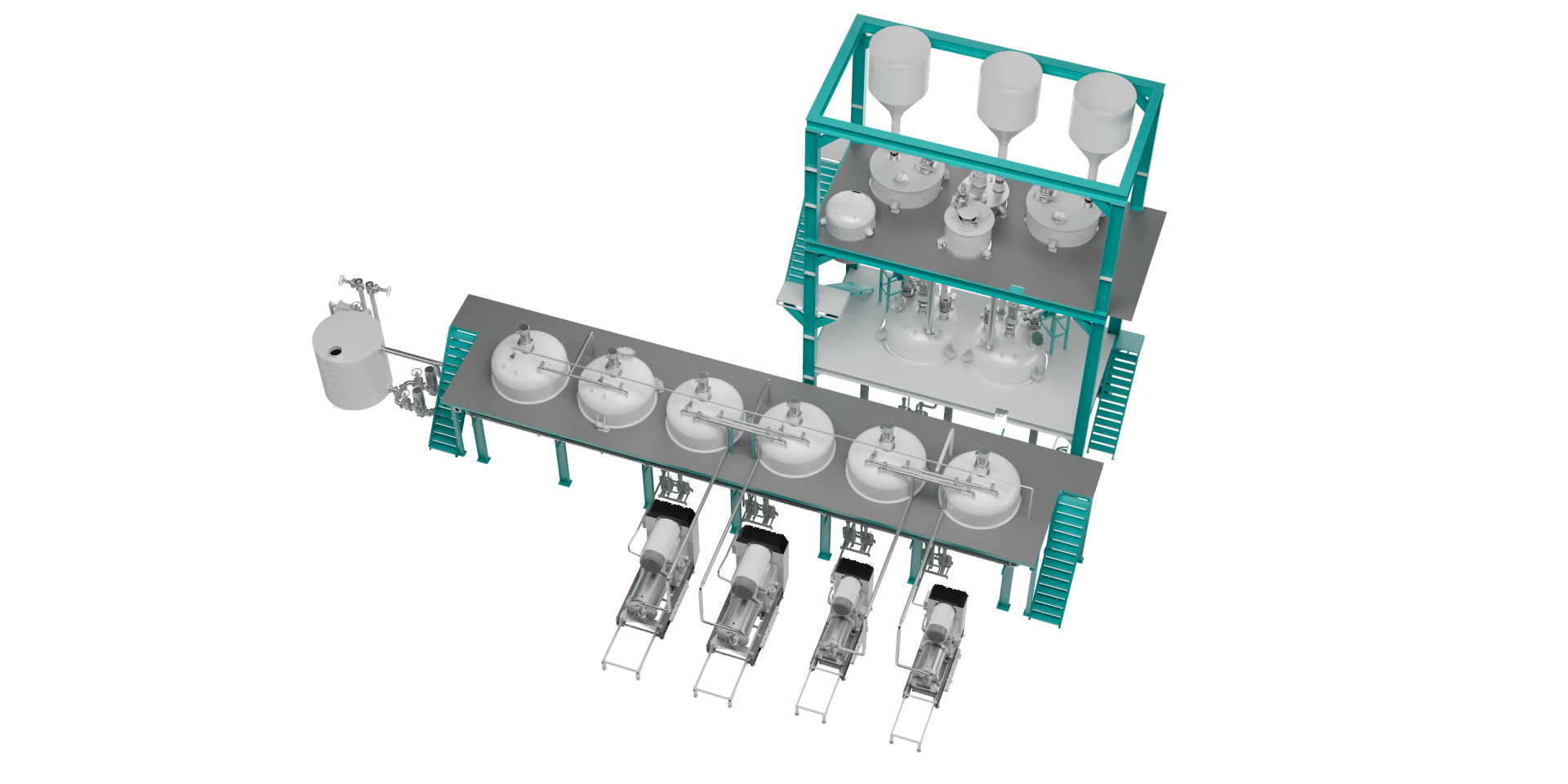

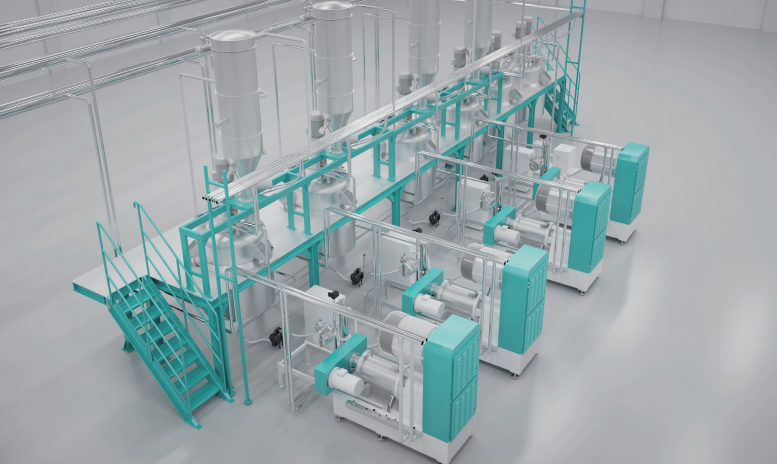

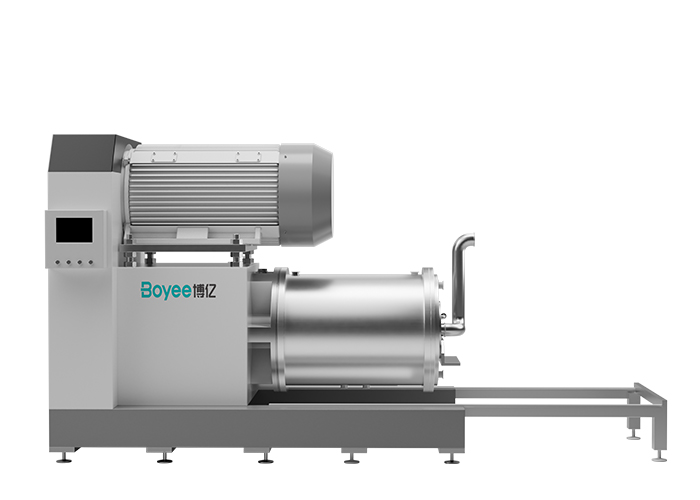

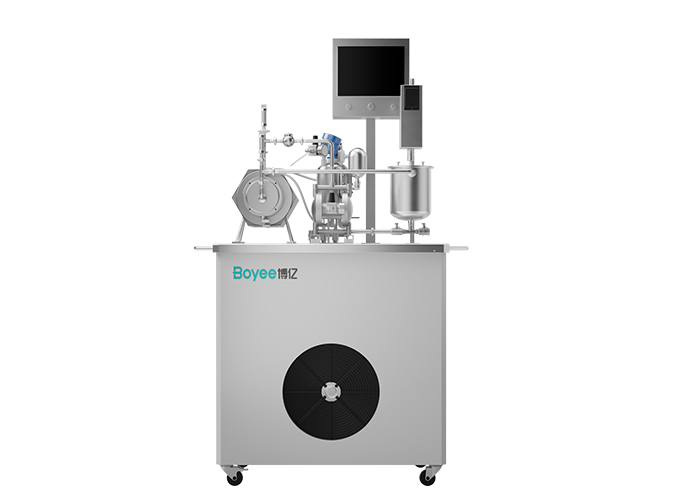

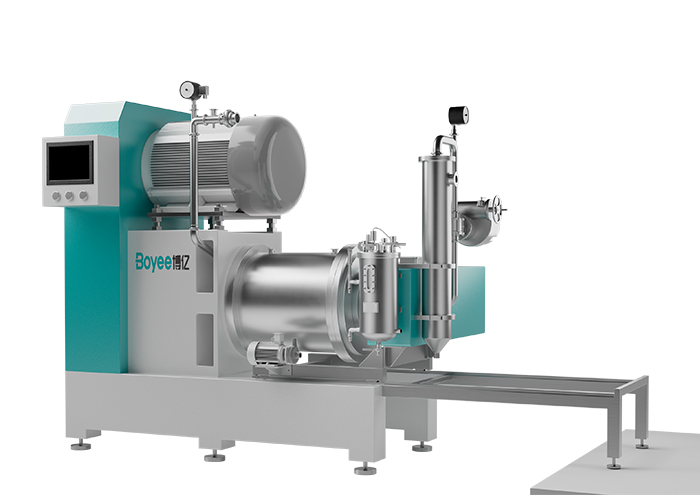

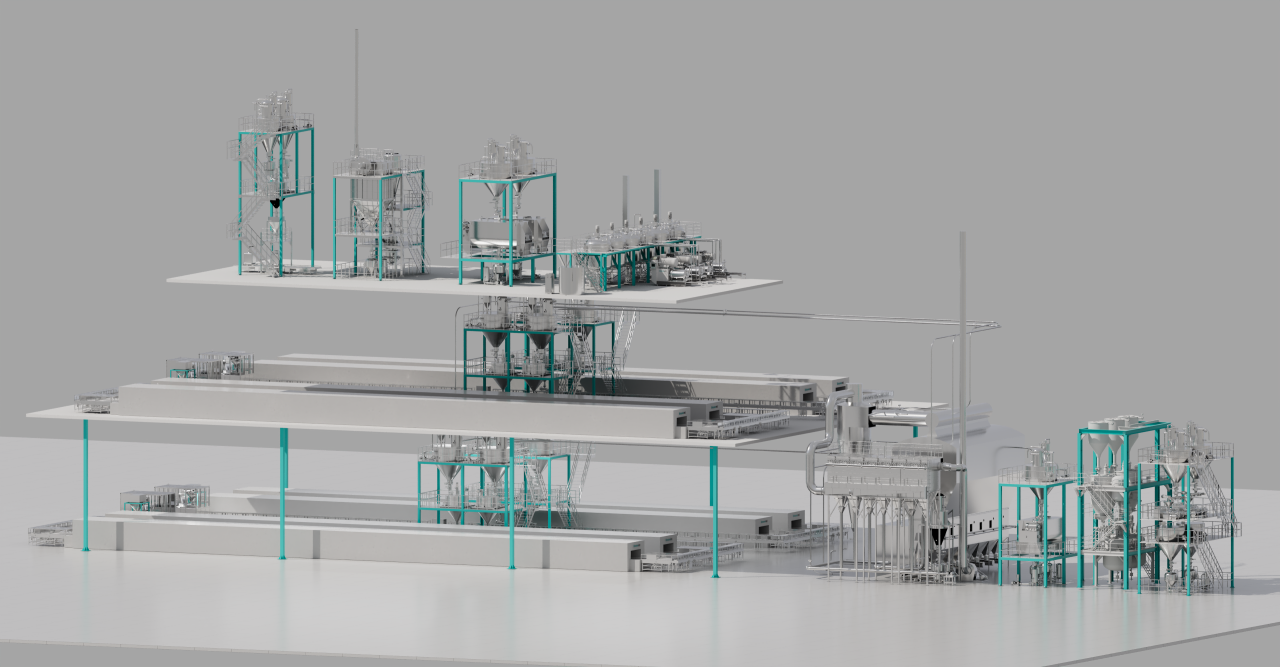

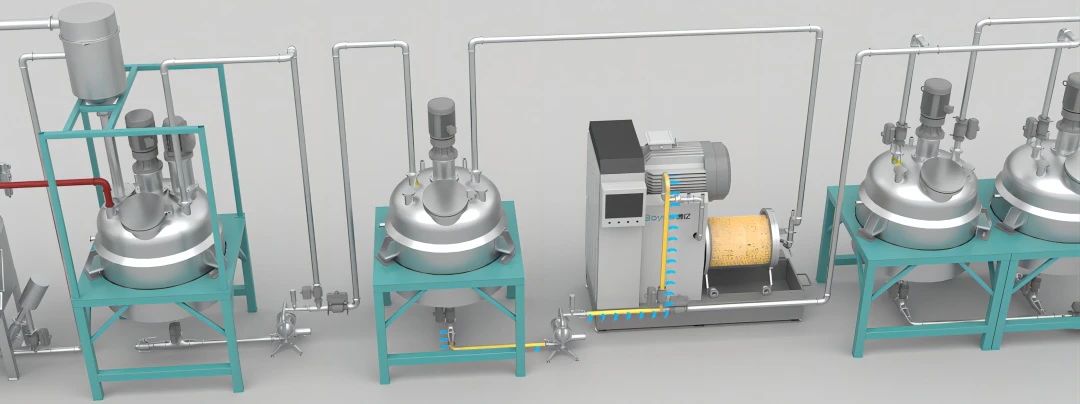

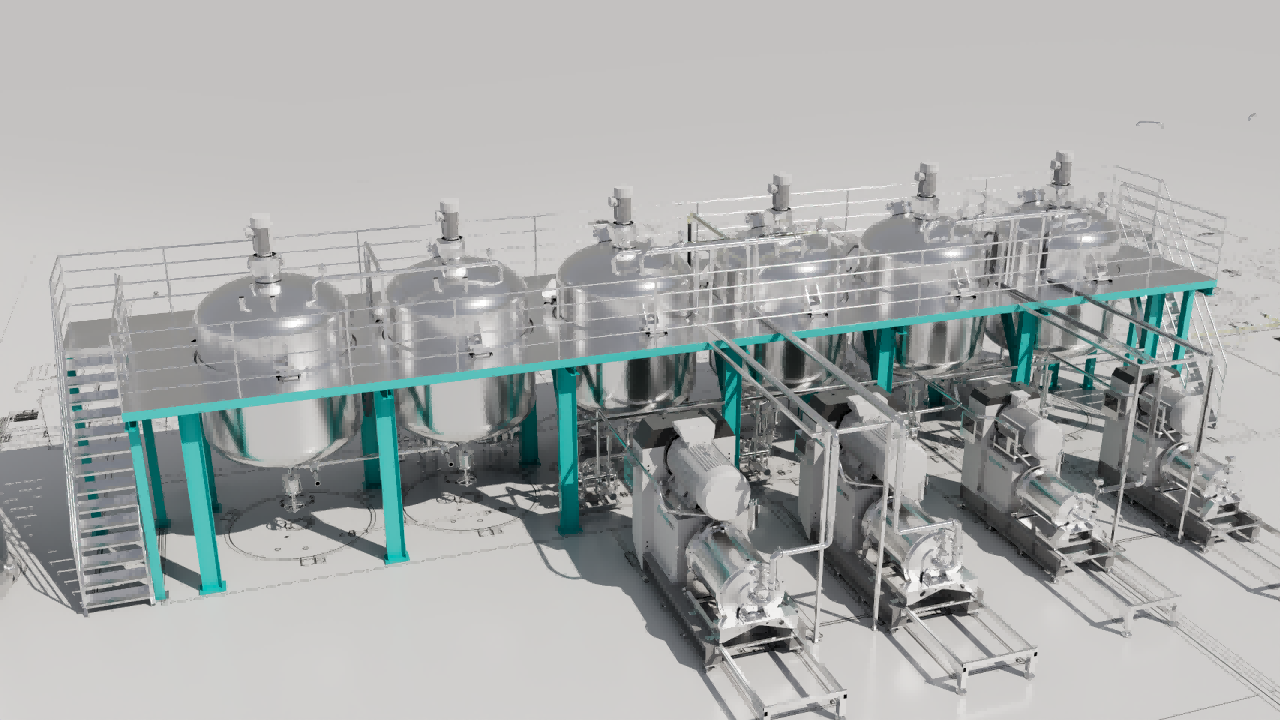

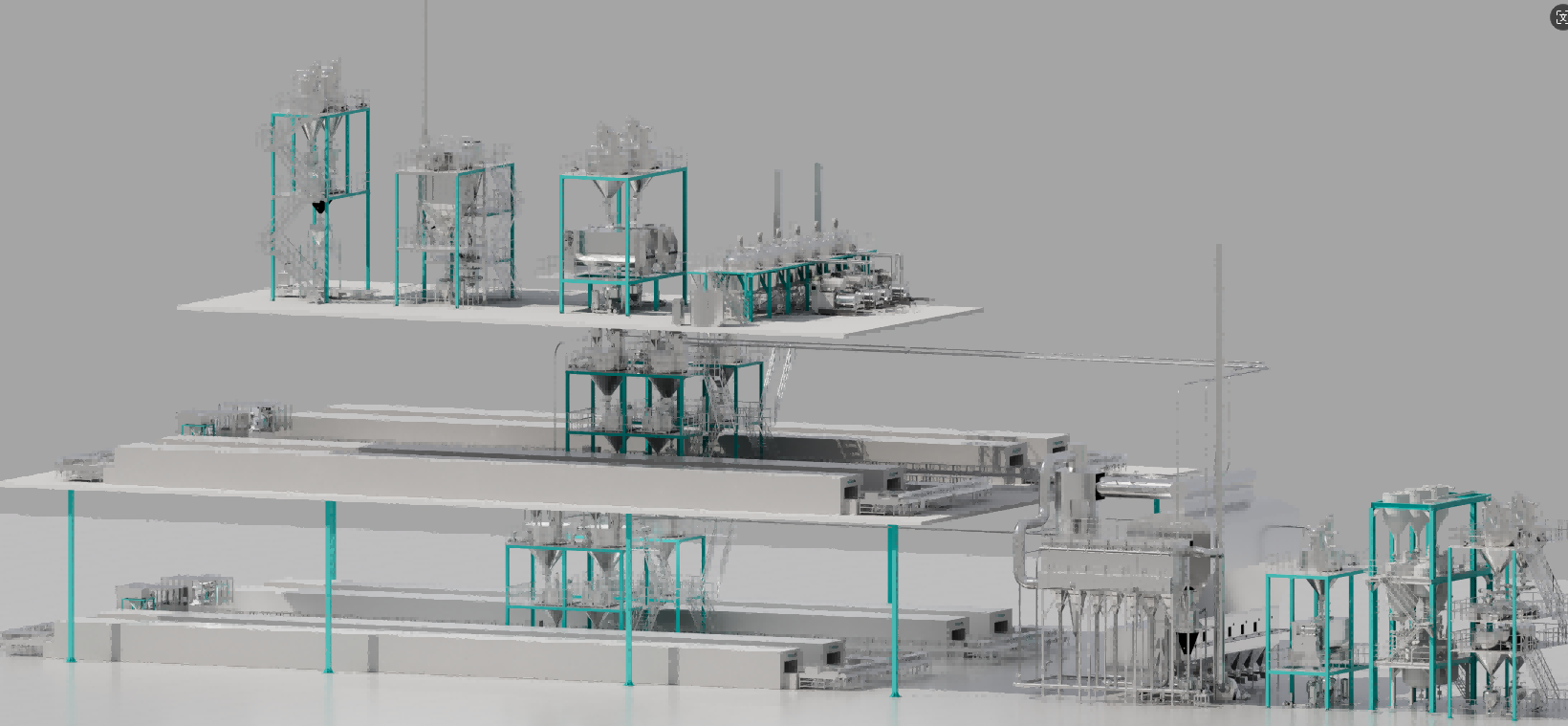

Conductive Paste Intelligent Production Line Solution Digital Inkjet Smart Production Line Food Intelligent Production Line Intelligent production line solutions for lithium-ion battery cathode materials. Silicon-Carbon Anode Intelligent Production Line NMM large flow screen type nano bead mill NMM multi-functional laboratory bead mill LMM ultra-fine centrifugal nano bead mill BYZr ceramic turbine bead mill SW universal nano bead mill Agitator tank Dispersing tank -

Application

Application

The equipment is more stable and the discharge is pure and fine

-

Service

Service

All for the customer, all for the customer

-

Media Center

Media Center

Become the core force in the field of global grinding dispersion

-

About Boyee

About Boyee

China all ceramic sanding machine pioneer

-

Contact us

Contact us

To provide customers with no time difference technical guidance and after - sales solutions